maxmuscle1

Board Rep

- Joined

- Apr 4, 2015

- Messages

- 25,534

- Reaction score

- 22,647

- Points

- 113

Aug, 2021

Gadeas Steroid intermediates : tried offering $176million to get AMRI Nanoparticle nano crystals , for steriod API market. (they said China would and is making it cheaper and the deal didn’t happen.

UGL/Pharma superfine/nanopowder anabolic steroid raws may be hitting the market. The only (micronized) raws I have seen : stanzolol for aqueous and test base for aqueous. They use the term micron or submicron based on the milling(through fine mesh (mechanical/ball/ and jet strainers). They have Wet milling and Dry milling. The reason behind micronizing a raw steroid powder is : increased bioavailability, more of the API(active pharmaceutical ingredient) in poorly soluble materials ie. carrier.

Wet milling works better but can skew results, wet milling does tend to create finer particles, it also increases costs and steps and adds many variables that dry milling doesn’t include.(most raw API Co. won’t do anything that increases their costs).

The important Part

REFERENCE FOR LAY PERSONS: milling -

*Mechanical- a particle size of 200 mesh (74 microns), with a typical mid-range particle size of 80 mesh (177 microns). Contamination is a problem because they pulverize with metal(why we see it in proper lab analysis) if I don’t see they tested for heavy metal contaminants, I won’t consider buying. (Not that I buy anything).

*Ball mills- cheapest and most used in pharmaceutical industry. This technique also serves as an intensive mixing technique capable of producing co-ground, pharmaceutical-**excipient mixtures (Sustanon/Blends)comprising amorphous drug forms mixed with suitable hydrophilic excipients at the molecular level.

*Jet Mills- jet mills allows the pharmaceutical manufacturer to grind a friable or crystalline material to an average particle size of 1 to 10 microns. One of the most important characteristics of a jet-milled product is the huge increase in surface area. Milling a material that’s 30 mesh (595 microns) down to 2,500 mesh (5 microns) results in 1,643,000 times the number of particles and a surface area that’s 118 times greater. This allows for faster chemical reaction times and improved pharmaceutical ingredient performance. They used four API compounds an increase of 50 percent in the solubility of an insoluble antimicrobial compound when the particle size was reduced from 2.4 μm(micron)to 800 or 300 nm(nano).

Max’s Thoughts:

This concludes my research(everyday), more to come. Soon very strong, less toxic orals, oils, injectables nasal, pellet, liquids, melting film strips will become available. Some using multiple technologies and changing the industry IR/ER/SR/CR oral and injectable (sustained/controlled/slow/long release). I can imagine a 400mg/ml testosterone propionate with zero chemicals added and No PIP, also; a 50mg testosterone propionate that equals 500mg because of increased bioavailability. They could also make 2000mg/2-3ml testosterone propionate that would release over a 14-90 day period, depending on what the customer needed.

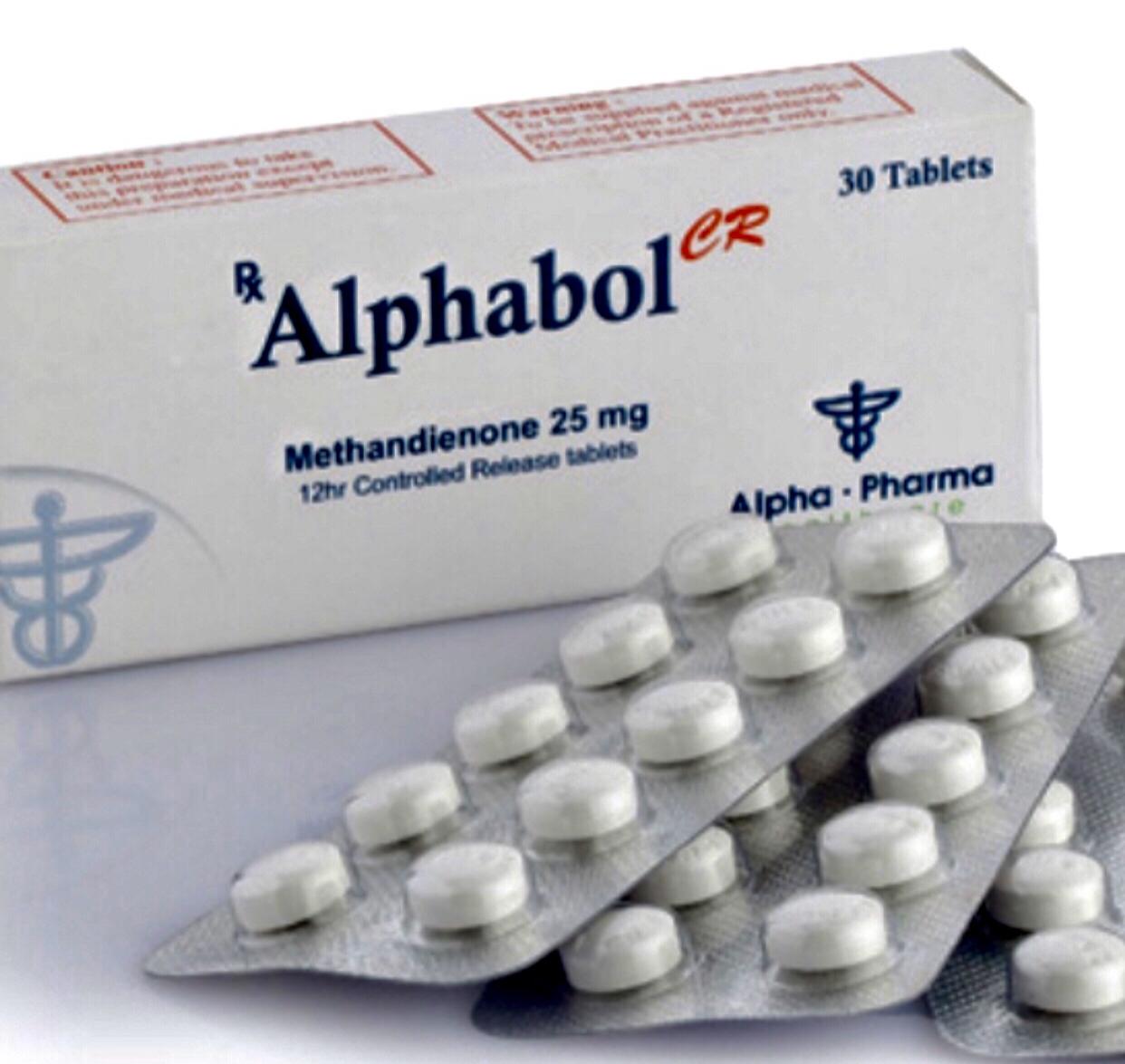

**They already have made a 100mg/.25ml and 200mg/.5ml testosterone that is currently trying to be marketed for subcutaneous injection, one has a 32g 4mm needle and the other is a needless auto injector(they are not yet available). Problem is: the Big Pharma companies are only interested in profits, they don’t see value in making a powerful or safe anabolic steroid....but they are all over Large dose long acting HGH and Peptides because they can charge $30,000 a month for it. Hopefully in the countries that anabolic steroids are legal for use or sale, we will see the first products like these . Alpha Pharm made a CR(controlled-release)12 hr Dianabol 25mg tab and Levitra 20mg film strips(like Listerine).

Gadeas Steroid intermediates : tried offering $176million to get AMRI Nanoparticle nano crystals , for steriod API market. (they said China would and is making it cheaper and the deal didn’t happen.

UGL/Pharma superfine/nanopowder anabolic steroid raws may be hitting the market. The only (micronized) raws I have seen : stanzolol for aqueous and test base for aqueous. They use the term micron or submicron based on the milling(through fine mesh (mechanical/ball/ and jet strainers). They have Wet milling and Dry milling. The reason behind micronizing a raw steroid powder is : increased bioavailability, more of the API(active pharmaceutical ingredient) in poorly soluble materials ie. carrier.

Wet milling works better but can skew results, wet milling does tend to create finer particles, it also increases costs and steps and adds many variables that dry milling doesn’t include.(most raw API Co. won’t do anything that increases their costs).

The important Part

REFERENCE FOR LAY PERSONS: milling -

*Mechanical- a particle size of 200 mesh (74 microns), with a typical mid-range particle size of 80 mesh (177 microns). Contamination is a problem because they pulverize with metal(why we see it in proper lab analysis) if I don’t see they tested for heavy metal contaminants, I won’t consider buying. (Not that I buy anything).

*Ball mills- cheapest and most used in pharmaceutical industry. This technique also serves as an intensive mixing technique capable of producing co-ground, pharmaceutical-**excipient mixtures (Sustanon/Blends)comprising amorphous drug forms mixed with suitable hydrophilic excipients at the molecular level.

*Jet Mills- jet mills allows the pharmaceutical manufacturer to grind a friable or crystalline material to an average particle size of 1 to 10 microns. One of the most important characteristics of a jet-milled product is the huge increase in surface area. Milling a material that’s 30 mesh (595 microns) down to 2,500 mesh (5 microns) results in 1,643,000 times the number of particles and a surface area that’s 118 times greater. This allows for faster chemical reaction times and improved pharmaceutical ingredient performance. They used four API compounds an increase of 50 percent in the solubility of an insoluble antimicrobial compound when the particle size was reduced from 2.4 μm(micron)to 800 or 300 nm(nano).

Max’s Thoughts:

This concludes my research(everyday), more to come. Soon very strong, less toxic orals, oils, injectables nasal, pellet, liquids, melting film strips will become available. Some using multiple technologies and changing the industry IR/ER/SR/CR oral and injectable (sustained/controlled/slow/long release). I can imagine a 400mg/ml testosterone propionate with zero chemicals added and No PIP, also; a 50mg testosterone propionate that equals 500mg because of increased bioavailability. They could also make 2000mg/2-3ml testosterone propionate that would release over a 14-90 day period, depending on what the customer needed.

**They already have made a 100mg/.25ml and 200mg/.5ml testosterone that is currently trying to be marketed for subcutaneous injection, one has a 32g 4mm needle and the other is a needless auto injector(they are not yet available). Problem is: the Big Pharma companies are only interested in profits, they don’t see value in making a powerful or safe anabolic steroid....but they are all over Large dose long acting HGH and Peptides because they can charge $30,000 a month for it. Hopefully in the countries that anabolic steroids are legal for use or sale, we will see the first products like these . Alpha Pharm made a CR(controlled-release)12 hr Dianabol 25mg tab and Levitra 20mg film strips(like Listerine).