Doomed

Registered

- Joined

- Jan 22, 2013

- Messages

- 559

- Reaction score

- 83

- Points

- 28

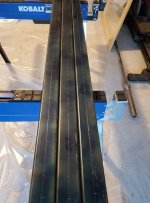

Little update, received my knurling attachment and used it last night at work. Love this thing. Only issue I had was the the dies dulled out after my eighth bar. So, now I am ordering another set of dies but this time hardened and hopefully that will workout. Plan on making a set of dumbbells from 5 pounds to 120 pounds.

Yard work and a heater.....

Yard work and a heater.....